The right infrastructure products form the backbone of every modern hospital, cleanroom, or diagnostic facility. From operation theatre doors and ICU doors to specialised cleanroom solutions and compliance-ready HVAC systems, every detail contributes to safety, efficiency, and infection control.

Healthcare, pharmaceutical, diagnostics, and electronics industries in India are increasingly adopting modular infrastructure and turnkey solutions to meet strict compliance standards such as NABH and WHO guidelines. This page highlights our key products, explains their importance, and addresses the most common buyer concerns to help you make informed decisions.

Why Choosing the Right Products Matters

- Infection Control: Improperly designed infrastructure can lead to contamination and hospital-acquired infections.

- Compliance: Facilities must meet NABH, GMP, and WHO standards to remain operational and audit-ready.

- Durability: High-traffic environments like ICUs and OTs demand long-lasting, low-maintenance products.

- Efficiency: Well-designed doors, HVAC systems, and filtration ensure smooth workflows and patient safety.

- Scalability: Products must support retrofits, expansions, and technology upgrades without disruption.

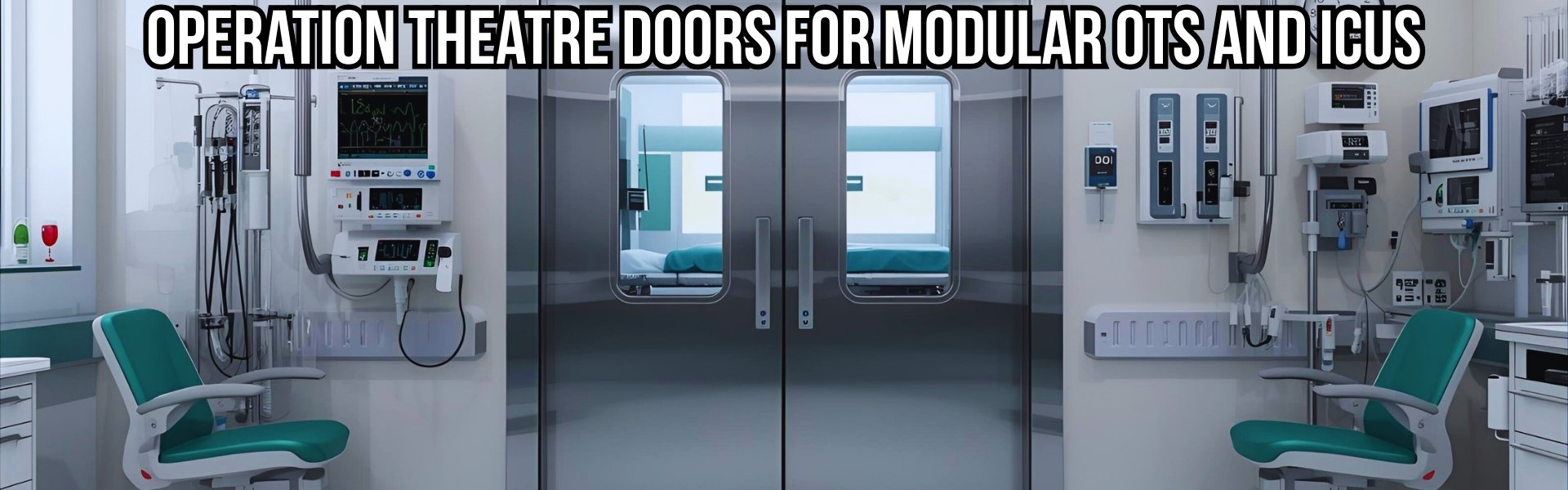

Operation Theatre & ICU Doors

Features of OT and ICU Doors

- Hermetically sealed designs to prevent cross-contamination.

- Smooth, anti-bacterial finishes for easy cleaning.

- Vision panels to allow monitoring without unnecessary entry.

- Options for sliding or swing operation based on space and workflow.

- Customised sizes to fit specific architectural requirements.

Applications

- Modular operation theatres

- Intensive care units

- Emergency wards

- Isolation rooms

For project-specific requirements in Gujarat, see our specialized range of Operation Theatre & ICU PUF Doors.

Cleanroom Doors and Controlled Environment Products

Importance of Cleanroom Doors

Cleanroom doors are critical for industries such as pharmaceuticals, electronics, and diagnostics laboratories where strict contamination control is required.

Key Benefits

- Durability: Constructed using stainless steel, aluminium, or HPL materials.

- Air Tightness: Prevents leakage between controlled zones.

- Compliance Ready: Meets GMP, NABH, and WHO cleanroom standards.

- Flexibility: Available as hinged or sliding types.

Explore our full Cleanroom Solutions to understand how these products integrate into larger turnkey projects.

Modular Operation Theatres

Modular OTs combine advanced products with smart engineering. They are equipped with:

- Operation theatre doors designed for sterility

- HEPA filtration systems maintaining laminar air flow

- Antistatic, epoxy, or vinyl flooring for safety

- HVAC systems ensuring correct positive/negative pressure balance

These features ensure compliance with NABH standards for hospitals and help reduce infection risks significantly. To learn more, visit our detailed page on Modular Operation Theatres.

HVAC and Filtration Systems

HVAC in Healthcare and Cleanrooms

HVAC systems in hospitals and cleanrooms are not simply about comfort. They play a direct role in patient outcomes, product quality, and compliance.

Key functions include:

- Controlling temperature and humidity for sensitive processes

- Maintaining positive pressure in OTs and negative pressure in isolation rooms

- Reducing airborne contaminants through filtration

- Supporting energy-efficient facility operations

HEPA Filtration

High Efficiency Particulate Air (HEPA) filters are essential in clean environments. According to WHO guidance, HEPA filters capture 99.97% of airborne particles ≥0.3 microns. These are used in:

- Operation theatres

- ICUs

- Pharmaceutical cleanrooms

- Diagnostics laboratories

Flooring Solutions: Epoxy, Vinyl, and Anti-Static Options

The floor is often overlooked, yet it is a major surface contributing to hygiene and compliance.

Flooring Types

- Epoxy Flooring: Seamless, chemical-resistant, and easy to clean.

- Vinyl Flooring: Cost-effective, flexible, and quick to install.

- Anti-Static Flooring: Prevents electrostatic discharge, essential in electronics and semiconductor cleanrooms.

Correct flooring selection is vital for maintaining sterility, durability, and safety in high-risk environments.

Buyer Concerns Addressed

When investing in healthcare and cleanroom infrastructure products, buyers often ask:

- Durability: Products are designed for long-term use with low maintenance.

- Infection Control: All products support NABH and WHO infection prevention guidelines.

- Certifications: Compliance with ISO, GMP, NABH, and international benchmarks.

- Lead Times: Modular and pre-engineered products reduce project timelines.

- Cost Factors: Pricing varies based on customisation, materials, and compliance requirements.

- Retrofit vs. New Build: Products are suitable for both new construction and retrofitting existing facilities.

Typical Project Workflow

- Requirement Analysis: Understand project scope (hospital, pharma, diagnostics, electronics).

- Design & Planning: Define layouts, product types, and compliance standards.

- Product Selection: Choose suitable doors, flooring, and HVAC systems.

- Installation: Products installed under cleanroom/OT protocols.

- Testing & Validation: Check compliance with NABH/WHO and client-specific standards.

- Handover & Training: Staff trained on product use and maintenance.

This structured approach ensures reliable, compliance-ready outcomes.

Frequently Asked Questions (FAQs)

Q1: What is the difference between OT doors and ICU doors?

OT doors are hermetically sealed and designed for sterility, while ICU doors focus more on accessibility and patient monitoring.

Q2: How do cleanroom doors differ from regular hospital doors?

Cleanroom doors provide airtight sealing, contamination control, and compliance with GMP standards.

Q3: Why is HVAC important in operation theatres?

HVAC ensures positive pressure, sterile airflow, and temperature/humidity control to reduce infection risks.

Q4: What is the role of HEPA filters in hospitals?

HEPA filters remove airborne contaminants, maintaining sterility in OTs and ICUs.

Q5: Which flooring is best for modular OTs?

Epoxy or vinyl flooring is preferred for modular OTs due to ease of cleaning, sterility, and durability.

Q6: Can these products be used in industries beyond healthcare?

Yes. Cleanroom doors, anti-static flooring, and HVAC systems are widely used in electronics, semiconductors, and food processing industries.

Q7: Are the products NABH compliant?

Yes. All products are designed to support NABH compliance when installed as per standards.

Q8: How much time does a turnkey cleanroom project take?

Typical timelines vary from 6–16 weeks depending on scope, approvals, and customisation.

Q9: Can products be customised?

Yes. Doors, flooring, and cleanroom systems can be tailored to project-specific requirements.

Q10: Where can I get technical specifications?

Visit the [Products — Operation theatre doors] section or contact our team for detailed specifications.

Final Thoughts

Healthcare and controlled environment infrastructure demands products that are durable, compliant, and designed for infection control. By choosing the right doors, flooring, HVAC, and filtration systems, facilities can achieve both regulatory compliance and operational efficiency.

At this point, it’s clear that not every vendor can deliver such specialised solutions. AUM Industries has established itself as a trusted partner in delivering turnkey projects, offering end-to-end expertise in modular OTs, ICUs, and cleanroom solutions. Learn more at AUM Industries.

Looking for the right products for your hospital, cleanroom, or industry-specific project? Reach out to our experts today via our [Contact Us] page to discuss your requirements and request a customised quote.