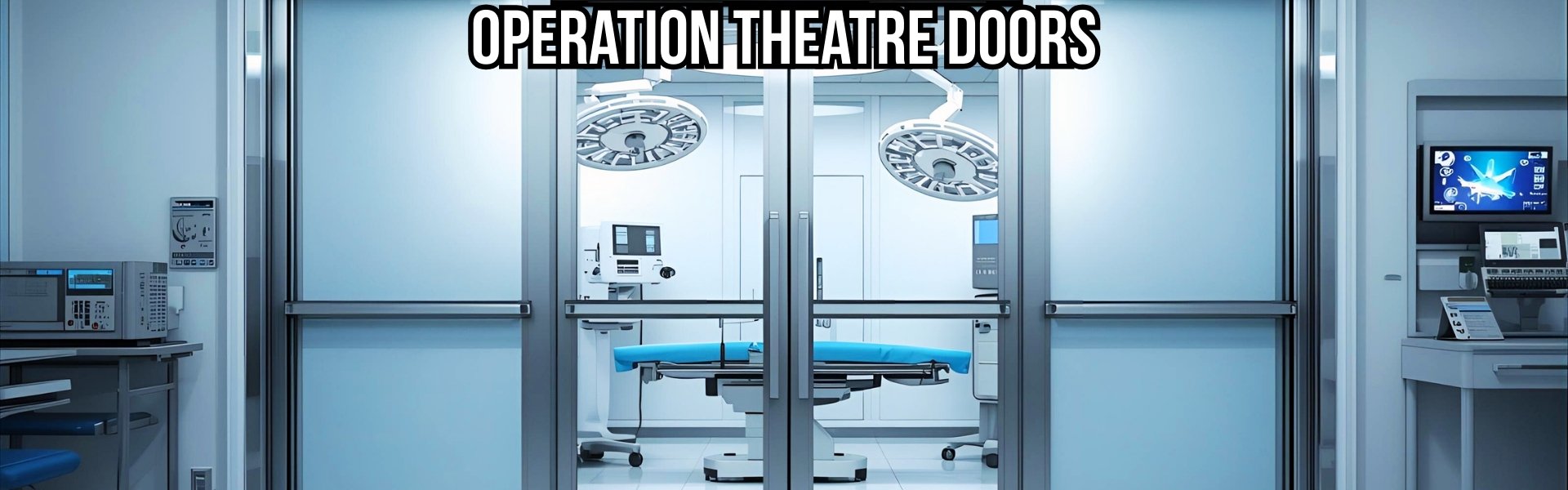

In the rapidly growing healthcare sector of India, particularly in Ahmedabad and Gujarat, hospitals and modular operation theatres (OTs) are under constant pressure to maintain the highest standards of infection control. With the increasing complexity of surgical procedures and the emergence of drug-resistant pathogens, the infrastructure supporting these facilities has never been more critical. Among the many elements of OT design, operation theater doors play a pivotal role in infection prevention, air quality management, and compliance with national and international standards.

AUM Industries, a trusted name in cleanroom and critical infrastructure turnkey solutions across India, emphasizes that choosing the right Operation Theater Door is not just about aesthetics or basic functionality—it is a cornerstone of patient safety, staff protection, and regulatory adherence.

This article explores why operation theater doors are indispensable in infection control, the types of doors used, their design and materials, compliance standards, and how hospitals, pharma cleanrooms, IVF centers, and other critical facilities can benefit from investing in high-quality doors.

Explore Operation Theatre & ICU PUF Doors

Understanding Infection Control in Hospitals

Importance of Infection Control

Hospital-acquired infections (HAIs) are a major concern worldwide. According to the World Health Organization (WHO), hundreds of millions of patients globally are affected by HAIs each year. In India, infection control remains a critical priority due to high patient volumes and resource constraints. Effective infection control not only improves patient outcomes but also reduces the burden on hospital resources.

Role of Environmental Controls

Infection control extends beyond sterilization of surgical instruments and hand hygiene. The design of hospital spaces, including airflow, surface materials, and barrier systems like ICU Doors and Operation Theater Doors, is essential for minimizing pathogen transmission. Doors act as the first line of defense against contamination by controlling access, maintaining pressure differentials, and supporting HEPA-filtered cleanroom environments.

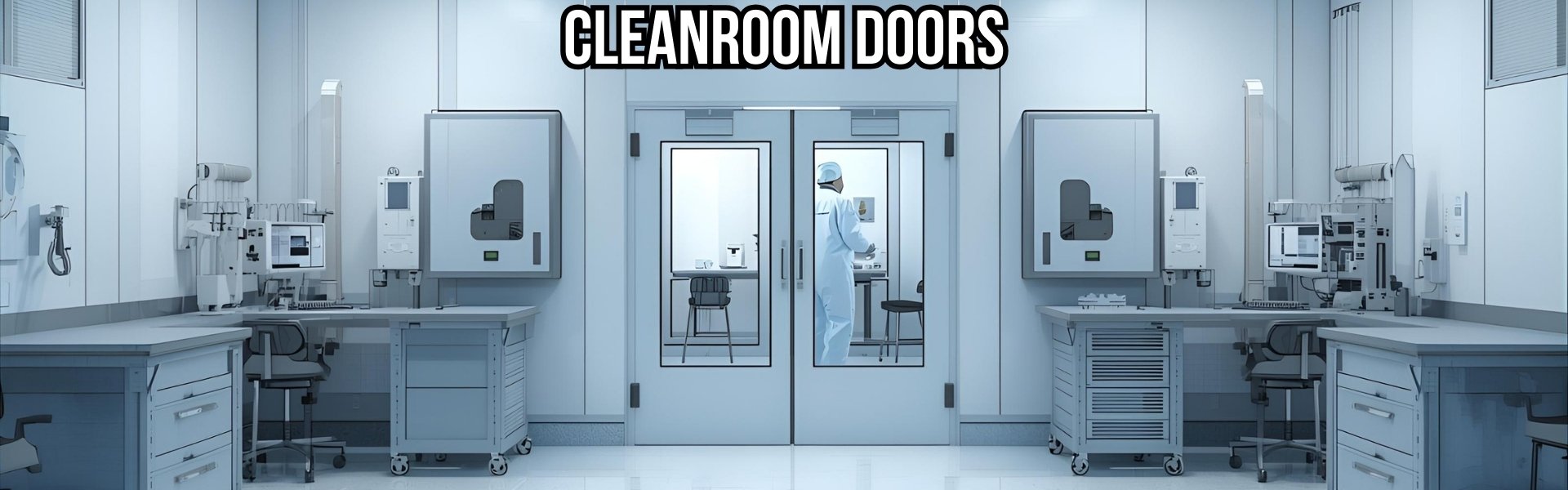

Learn more about Cleanroom Solutions

How Operation Theater Doors Contribute to Infection Control

1. Maintaining Positive Pressure

Operation theatres typically operate under positive pressure relative to surrounding areas. This means that air flows out of the OT, preventing unfiltered external air from entering. High-quality PUF Insulated Doors with airtight seals are essential to maintaining this positive pressure, which significantly reduces the risk of airborne pathogens.

2. Controlling Airborne Contaminants

Surgical procedures are highly sensitive to airborne particles, including dust, microorganisms, and allergens. Cleanroom Doors equipped with hermetic sealing prevent external contaminants from infiltrating sterile environments. This is especially crucial in modular OTs, IVF labs, and pharmaceutical cleanrooms where even minor contamination can compromise outcomes.

3. Minimizing Touchpoints and Surface Contamination

Door design affects how often staff must touch surfaces. Automatic or semi-automatic ICU Doors and OT Doors reduce manual contact, thereby lowering the risk of cross-contamination. PUF insulated and flush doors are easy to clean and disinfect, further contributing to a hygienic environment.

4. Fire and Emergency Compliance

Fire Exit Doors and emergency access doors are integrated into OT and ICU designs without compromising infection control. High-quality doors maintain sterile conditions while providing safe evacuation routes in case of emergencies.

Types of Operation Theater Doors and Their Applications

1. PUF Insulated Doors

Polyurethane Foam (PUF) insulated doors are preferred for OTs and ICUs due to their thermal insulation, airtight properties, and durability. They help maintain temperature and humidity control, essential for patient safety and equipment performance.

Applications:

- Hospitals & Surgical Centres

- Pharma Cleanrooms

- IVF & Pathology Labs

2. Hermetic and Cleanroom Flush Doors

These doors provide a completely sealed environment, preventing air leakage and maintaining cleanroom standards. Their smooth surfaces make them easy to disinfect.

Applications:

- Semiconductor & Electronics Facilities

- Cosmetic & Chemical Plants

- Educational & Research Labs

3. ICU Doors

ICU Doors are designed to support patient monitoring, emergency interventions, and infection control simultaneously. They often feature noise insulation, observation panels, and automated opening systems.

Applications:

- ICU Setup

- High-dependency wards

4. Operation Theater Doors

OT doors are engineered for surgical environments, ensuring sterility, minimal air leakage, and seamless integration with HVAC and HEPA filtration systems.

Applications:

- Modular Operation Theatres

- Hospitals & Surgical Centres

5. Emergency Exit and Fire Doors

Designed for compliance with NABH and ISO standards, these doors provide rapid egress without compromising sterile conditions. They are commonly used in hospitals, pharma plants, and industrial cleanrooms.

Key Features of Infection Control-Friendly Doors

- Airtight Seals: Prevents unfiltered air from entering sterile zones.

- PUF Panels: Insulation supports temperature and humidity control.

- Antimicrobial Surfaces: Reduces bacterial colonization.

- Automatic Operation: Minimizes touchpoints and contamination.

- Durable Materials: Supports repeated disinfection.

- Compliance Ready: Meets NABH, ISO, and WHO standards.

Installation and Maintenance Considerations

Professional Installation

Proper installation is critical to ensure airtightness, pressure control, and durability. Manufacturers like AUM Industries provide turnkey solutions for hospitals, IVF labs, and cleanrooms, handling everything from design to installation.

Regular Maintenance

Periodic inspections, lubrication of hinges, and cleaning of seals maintain the door’s performance. Using compatible disinfectants ensures longevity and effectiveness in infection control.

Integration with HVAC and HEPA Systems

OT and cleanroom doors work in tandem with ventilation systems to maintain laminar airflow, HEPA filtration efficiency, and controlled environmental parameters, crucial for sterile operations.

Explore Modular Operation Theatres

Case Studies: Indian Hospitals & Pharma Facilities

1. Ahmedabad-Based Hospital OT Setup

A multi-specialty hospital in Ahmedabad upgraded its OTs with PUF insulated OT doors from AUM Industries. Positive pressure maintenance improved significantly, and post-installation microbial contamination levels dropped by 40%, according to internal quality audits.

2. Pharma Cleanroom in Vadodara

A pharmaceutical manufacturing unit in Vadodara implemented cleanroom flush doors across its QA/QC and production areas. The doors maintained ISO Class 7 cleanroom standards, ensuring compliance during regulatory inspections.

3. IVF Centre Infection Control

An IVF centre in Gujarat installed hermetic OT doors with automated operation, reducing human touchpoints and ensuring the sterility of embryo handling areas.

Benefits of High-Quality OT Doors for Hospitals and Cleanrooms

- Enhanced Infection Control: Minimizes HAIs and contamination risks.

- Regulatory Compliance: Aligns with NABH, ISO, and WHO guidelines.

- Energy Efficiency: PUF insulated doors reduce HVAC load.

- Durability & Longevity: Resists wear from constant use and cleaning.

- Improved Workflow: Automatic and ergonomic designs aid staff efficiency.

Discover Operation Theater Door Manufacturer Solutions

Choosing the Right Operation Theater Door Manufacturer

When selecting a manufacturer, hospitals and pharma facilities should consider:

- Experience & Expertise: Proven track record in cleanroom and OT solutions.

- Compliance & Certifications: NABH, ISO, and WHO-aligned products.

- Turnkey Solutions: Design, installation, and maintenance support.

- Customization: Ability to tailor doors for ICUs, modular OTs, and cleanrooms.

AUM Industries is a trusted choice

FAQs

1. Why are PUF insulated doors preferred for OTs?

PUF doors provide thermal insulation, airtightness, and durability, which are critical for infection control and maintaining sterile environments.

2. How do OT doors maintain positive pressure?

Hermetic seals and airtight construction prevent outside air from entering, ensuring airflow moves outward, reducing contamination risks.

3. Can ICU doors be automated?

Yes, many ICU doors feature automatic opening systems to minimize touchpoints and improve hygiene.

4. Are cleanroom flush doors suitable for pharmaceutical facilities?

Absolutely, they maintain ISO cleanroom standards and support infection control in sensitive pharma and diagnostic areas.

5. How often should OT and ICU doors be maintained?

Regular maintenance, including inspection, cleaning, and seal checks, should be performed quarterly or as recommended by the manufacturer.

6. Do fire exit doors affect infection control?

Modern fire exit doors are designed to maintain sterile conditions while providing emergency egress, balancing safety and hygiene.

7. What compliance standards should be considered?

NABH, ISO 14644, and WHO guidelines are essential benchmarks for OT and cleanroom doors.

Final Thoughts

High-quality operation theater doors are more than just entry points; they are critical components of hospital and cleanroom infection control strategies. By maintaining positive pressure, controlling airborne contaminants, and reducing surface contamination, these doors protect patients, staff, and valuable equipment.

AUM Industries, headquartered in Ahmedabad with manufacturing facilities in Vadodara, provides expert Turnkey Projects and Cleanroom Solutions, delivering PUF Insulated Doors, OT Doors, ICU Doors, and Fire Exit Doors that meet the highest standards of Indian and international healthcare infrastructure. For hospitals, pharma cleanrooms, IVF centers, and industrial cleanrooms across India, investing in high-quality doors is investing in safety, efficiency, and compliance.

Contact AUM Industries for Customized Solutions