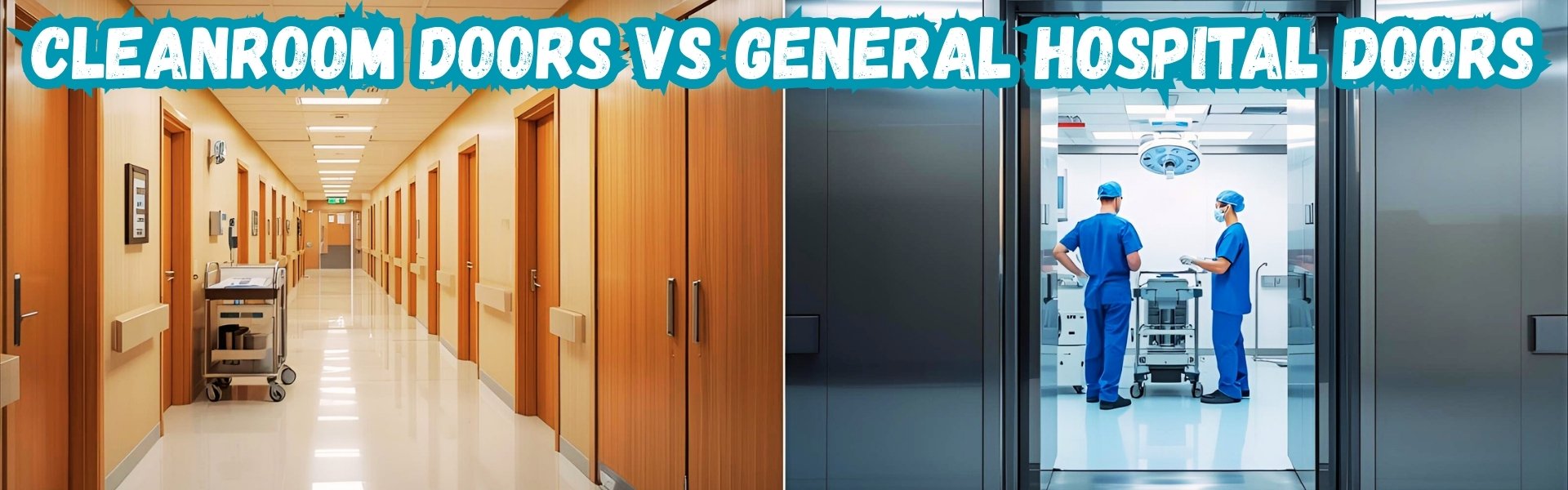

Every square foot of a hospital serves a purpose — and the doors that separate one zone from another are far more than simple passageways. They control air quality, pressure, hygiene, infection risk, and even the psychology of patients and staff. Yet, one of the most common confusions among hospital planners and contractors is the difference between cleanroom doors and general hospital doors.

While both are used in healthcare environments, their functions, construction, and performance standards are worlds apart. Understanding these differences is critical for anyone involved in ICU setup, modular operation theatres, pharma units, or turnkey cleanroom solutions across India — especially in healthcare hubs like Ahmedabad and Gujarat, where quality infrastructure defines compliance and care.

Understanding the Purpose Behind Each Door

Before comparing specifications, it’s important to understand the role each door plays.

General hospital doors focus primarily on safety, accessibility, and patient comfort. They separate rooms, manage traffic, and ensure easy movement of patients, trolleys, and equipment. These doors are often used in wards, consultation rooms, waiting areas, and general utility zones.

Cleanroom doors, on the other hand, are engineered for controlled environments — areas where contamination, airflow, and microbial load must be strictly managed. These include operation theatres, ICUs, pharmaceutical units, diagnostic labs, IVF centres, and biosafety environments.

They are part of a complete cleanroom ecosystem — along with PUF insulated panels, air handling units, HEPA filters, and pressure control systems — that maintain sterile conditions in compliance with WHO, NABH, and GMP standards.

Key Structural Differences Between Cleanroom and General Hospital Doors

1. Design Philosophy: Containment vs. Convenience

General hospital doors are designed for convenience. They are made for heavy use, quick access, and smooth movement. Materials may vary from wood laminate to mild steel or powder-coated metal, depending on the area.

Cleanroom doors, however, are designed for containment — to maintain positive or negative air pressure, prevent contamination, and minimize particulate generation. Every component — from door leaf to gasket — supports air-tight performance.

For example, in a modular OT setup, hermetically sealed Operation Theatre Doors ensure the air pressure gradient remains intact even during frequent entries and exits.

Explore specialized OT door designs at Operation Theater Doors.

To understand NABH’s stance on infection control infrastructure, refer to the official NABH portal.

2. Material Composition and Finish

Cleanroom doors use non-shedding, antimicrobial, and corrosion-resistant materials such as powder-coated galvanized steel, stainless steel, or HPL (High Pressure Laminate). These finishes prevent microbial growth and are easy to disinfect.

General hospital doors can use laminate, mild steel, or even hardwood — ideal for non-sterile areas but unsuitable for controlled zones where surface porosity can trap contaminants.

High-performance cleanroom doors, such as those supplied under PUF Insulated Doors, also offer enhanced insulation and energy efficiency — essential for maintaining temperature-sensitive environments like ICUs and pharma production areas.

According to WHO’s infection prevention guidelines, smooth, cleanable, and moisture-resistant surfaces are non-negotiable in sterile healthcare zones.

3. Air-Tightness and Pressure Control

A defining difference lies in air-tightness. Cleanroom and OT doors are hermetically sealed with EPDM gaskets, ensuring minimal air leakage. This helps maintain positive pressure in sterile rooms (like OTs) and negative pressure in isolation zones.

In contrast, general hospital doors lack such sealing systems — acceptable for patient wards or administrative areas but inadequate for critical zones where air quality directly impacts patient outcomes.

Hospitals planning a new ICU setup can learn more about suitable door systems at ICU Setup.

For technical parameters on healthcare air quality, visit the Ministry of Health & Family Welfare guidelines.

4. PUF Insulation and Energy Efficiency

PUF (Polyurethane Foam) insulation is a major differentiator. Cleanroom and OT doors often integrate a PUF core — a lightweight yet highly effective insulator that maintains temperature stability and enhances door rigidity.

This feature is crucial for ICUs, operation theatres, pharma production, and biosafety labs, where HVAC systems must maintain a consistent temperature and humidity balance.

General hospital doors, typically non-insulated, allow thermal drift — leading to higher HVAC load and reduced efficiency in controlled environments.

AUM’s PUF Insulated Doors provide excellent thermal insulation and soundproofing, making them ideal for both healthcare and pharma cleanrooms.

The WHO also emphasizes thermal efficiency in medical facility design to reduce operational energy costs.

5. Ease of Cleaning and Maintenance

Cleanroom doors are built with flush surfaces, no crevices, and radiused corners to prevent dust accumulation. Hinges, handles, and vision panels are designed to resist microbial buildup and are compatible with hospital-grade disinfectants.

General hospital doors often include exposed hinges or joints, which can harbor dust and bacteria over time. While sufficient for administrative areas, they fall short in clean zones.

Hospitals upgrading OTs in Gujarat can explore modular cleanroom configurations at Modular Operation Theater

To explore hygiene maintenance standards, review WHO’s Infection Prevention and Control manual.

6. Compliance Standards and Certifications

Cleanroom and OT doors are tested and certified for NABH, GMP, and WHO compliance. They support the stringent requirements of air-tightness, fire safety, and cleanroom classification (ISO 14644).

General hospital doors may adhere to fire safety and accessibility norms but do not undergo particulate or microbial validation.

For example, ICU Doors combine compliance with ergonomic operation, offering both manual and automatic configurations tailored to critical care environments.

Healthcare administrators can review WHO guidelines on cleanroom classification for deeper technical understanding.

7. Safety and Fire Resistance

Every hospital must prepare for emergencies — and that includes fire safety. Cleanroom doors are often rated fire-retardant up to 60–120 minutes, depending on design, while maintaining their air-tightness.

General hospital doors may have basic fire ratings but usually lack the layered construction that prevents smoke infiltration or flame spread.

Hospitals can review available options under Fire Exit Doors.

For regulatory fire safety norms, see Ministry of Health India’s Hospital Safety Guidelines.

Where Cleanroom Doors Are Used (and Why They Matter)

- Operation Theatres: Maintain sterile zones and pressure control.

- ICUs and Isolation Rooms: Prevent cross-contamination.

- Pharmaceutical Units: Ensure GMP compliance and dust-free environments.

- Diagnostic & IVF Labs: Maintain Class 1000–10000 cleanroom standards.

- R&D Facilities: Protect sensitive processes and materials.

Each of these spaces demands precise environmental control, where a cleanroom door acts as a physical and microbial barrier.

For turnkey cleanroom planning and installation, see Cleanroom Solutions.

Refer to WHO’s GMP for Pharmaceuticals for environmental classifications and door standards.

Why the Difference Matters in Ahmedabad and Gujarat

Ahmedabad and Gujarat are among India’s fastest-growing healthcare and pharmaceutical corridors. With NABH-accredited hospitals, large pharma units, and global medical tourism, the region demands world-class cleanroom infrastructure.

Hospitals and pharmaceutical units in Ahmedabad increasingly choose hermetically sealed OT doors, PUF-insulated ICU doors, and flush cleanroom doors to meet both regulatory and operational needs.

Whether it’s a new ICU setup in a tertiary hospital or a turnkey cleanroom project for a pharma manufacturer, the right door system ensures infection safety, compliance, and efficiency.

Healthcare facilities in the region can explore customized solutions through Turnkey Projects.

To align with NABH norms for infection control, administrators can refer directly to the NABH Accreditation Guidelines.

FAQs: Cleanroom Doors vs. General Hospital Doors

1. Why can’t general hospital doors be used in operation theatres?

Because general doors lack hermetic sealing and PUF insulation, they allow air leakage and microbial contamination. OTs require airtight, flush-mounted cleanroom doors that maintain sterile pressure zones.

2. What is a hermetically sealed door?

A hermetically sealed door uses specialized gaskets and mechanisms that ensure no air or particle leakage — essential in OTs and isolation rooms.

3. Are PUF insulated doors energy-efficient?

Yes. The PUF core minimizes thermal loss, reducing HVAC loads and maintaining consistent room temperature — crucial for ICUs and pharma units.

4. Do cleanroom doors meet fire safety standards?

High-quality cleanroom doors are designed with fire-retardant cores and smoke seals, offering both safety and compliance.

5. Can cleanroom doors be automated?

Absolutely. Cleanroom and OT doors can integrate with sensors or touchless systems for improved hygiene and ease of use.

6. What materials are best for cleanroom doors?

Powder-coated steel, stainless steel, or HPL surfaces are preferred for their smooth, antimicrobial finish and durability.

7. How often should cleanroom doors be serviced?

Regular inspection every six months ensures gasket integrity, smooth operation, and compliance with NABH/WHO standards.

8. Are cleanroom doors costlier than general hospital doors?

Initially yes, but they reduce infection risk, HVAC costs, and maintenance — offering a far better lifecycle value.

9. What’s the role of PUF panels in cleanroom design?

PUF panels create insulated, non-shedding wall systems that complement cleanroom doors to maintain sterile and energy-efficient spaces.

10. Where can hospitals in Gujarat source compliant cleanroom doors?

AUM Industries in Ahmedabad provides NABH-compliant cleanroom, OT, and ICU doors designed specifically for Indian healthcare infrastructure.

Final Thoughts

Cleanroom doors and general hospital doors may look similar, but their engineering purpose differs entirely. One is meant for comfort and access; the other for control and containment.

As healthcare facilities across Gujarat and India continue upgrading to meet NABH, WHO, and GMP standards, the choice of doors plays a decisive role in safety, performance, and compliance.

For hospitals, pharma companies, and contractors seeking Operation Theatre Doors, ICU Doors, or PUF Insulated Doors, AUM Industries stands as a trusted manufacturer and turnkey solutions provider based in Ahmedabad, Gujarat — delivering precision-engineered doors and complete cleanroom setups that truly safeguard healthcare spaces.

Visit aumindustriesmfg.com to explore customized solutions for your next healthcare or pharma infrastructure project.