Modern healthcare demands more than skilled doctors and advanced medical devices—it demands safe, sterile, and compliant environments where life-saving procedures can take place without the risk of infection or contamination. This is where Modular Operation Theatres (MOTs) come into play.

Unlike conventional operation theatres, modular OTs are custom-built, technologically advanced, and designed with strict infection control measures. They combine precision engineering, high-grade materials, and advanced air-handling systems to create a surgical environment that meets the highest global standards, including NABH and WHO guidelines.

For hospitals, surgical centres, and specialty healthcare providers, a modular OT is not just an infrastructure upgrade—it’s an investment in patient safety, efficiency, and long-term credibility.

What is a Modular Operation Theatre?

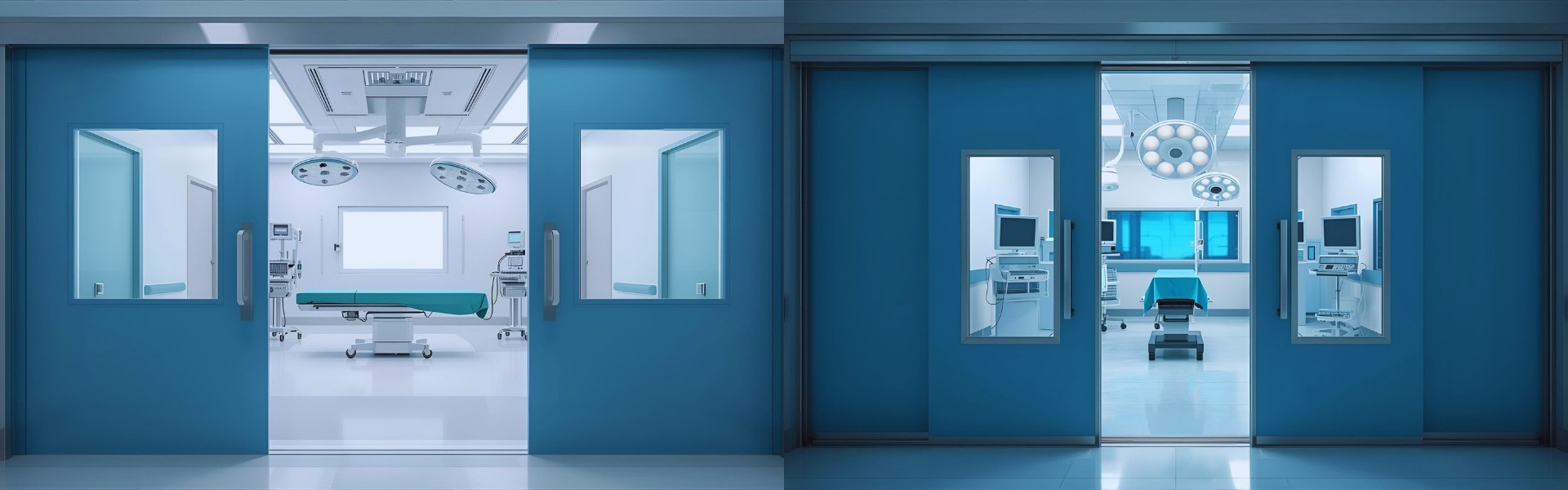

A Modular Operation Theatre is a pre-engineered, factory-fabricated, and site-assembled sterile environment specifically designed for surgeries and other critical medical procedures. Unlike brick-and-mortar OTs, modular OTs are made using modular panels, doors, ceiling systems, and integrated equipment, allowing faster installation, better flexibility, and easier maintenance.

These systems are designed to be:

- Hermetically sealed to prevent contamination

- Easily cleanable with flush surfaces and minimal joints

- Energy efficient with HVAC systems optimized for sterility

- Adaptable to new surgical equipment and medical advancements

👉 If you want to understand the doors and partitions used in these environments, explore our detailed guide on PUF Insulated Doors in Ahmedabad.

Why Modular Operation Theatres are Essential

1. Infection Control

Airborne infection is one of the leading causes of post-surgical complications. Modular OTs integrate HEPA filtration, laminar airflow, and controlled pressure differentials to minimize microbial load.

2. Compliance with Standards

Hospitals today are expected to comply with NABH accreditation in India and global WHO guidelines. Modular OTs are designed to meet these benchmarks seamlessly.

3. Faster Project Execution

Unlike conventional construction that can take months, modular OTs can be installed in 6–12 weeks, ensuring hospitals become operational faster.

4. Cost-Efficiency

Although modular OTs may seem like a premium investment, they offer significant savings in terms of reduced downtime, easier upgrades, and lower maintenance costs.

5. Flexibility & Scalability

Hospitals can expand or reconfigure modular OTs with minimal disruption—something conventional OTs cannot match.

Key Components of a Modular OT

A modular OT is a system of systems. Every component is carefully designed for sterility, functionality, and durability.

1. Walls & Partitions

- Made with PUF panels, stainless steel, or GI with powder coating.

- Seamless, flush finish with antimicrobial coating.

- Resistant to microbial growth and easy to disinfect.

2. Doors & Viewing Panels

- Hermetically sealed OT doors with smooth finish.

- PUF insulated doors to maintain temperature control.

- Viewing panels with double-glazed glass for staff observation.

3. Ceiling Systems

- Integrated with laminar air flow (LAF) systems.

- Provision for medical lights, pendants, and gas supply units.

4. HVAC & Filtration Systems

- Air Handling Units (AHUs) with HEPA filters.

- Pressure gradient maintenance (positive pressure inside OT).

- Temperature (18–25°C) and humidity control (45–55%).

For deeper insight into HVAC and cleanroom setups, see our dedicated page on Cleanroom Solutions.

5. Flooring Solutions

- Epoxy flooring for seamless sterility.

- Vinyl flooring for flexibility and durability.

- Anti-static options for sensitive equipment.

6. Fire & Safety Compliance

- Fire exit doors with panic bars.

- Smoke detectors and emergency systems integrated.

Industries That Benefit from Modular OTs

While primarily associated with hospitals, modular OT principles apply across several industries:

- Hospitals & Surgical Centres – Safer surgical environments.

- Pharmaceuticals – For sterile R&D labs and production facilities.

- Diagnostics Laboratories – For contamination-free testing zones.

- Electronics & Semiconductors – Dust-free production floors.

- Food & Beverages – Hygienic environments for safe production.

FAQs About Modular Operation Theatres

Q1. How long does it take to build a modular OT?

Most medium-sized modular OTs can be installed in 8–12 weeks, depending on complexity.

Q2. Are modular OTs expensive compared to conventional OTs?

Initial investment is higher, but modular OTs save costs in the long run through faster setup, reduced downtime, and better infection control.

Q3. What standards do modular OTs follow in India?

They are designed to comply with NABH standards and global WHO infection control guidelines.

Q4. Can existing OTs be converted into modular OTs?

Yes. Retrofitting solutions are available to upgrade conventional OTs into modular ones.

Q5. What makes modular OTs better than traditional ones?

- Better sterility

- Faster project timelines

- Easier scalability

- Compliance assurance

Common Misconceptions

- “Modular OTs are only for large hospitals.”

Not true—small and mid-size hospitals are increasingly adopting modular OTs due to affordability and scalability. - “They are difficult to maintain.”

On the contrary, modular OTs are designed for easy cleaning and long-term durability. - “Compliance is optional.”

Non-compliance with NABH/WHO can result in regulatory penalties and patient safety issues.

Benefits of Choosing a Modular OT Partner

- End-to-end responsibility with turnkey project execution.

- Compliance expertise with NABH and WHO standards.

- Customized solutions for different hospital sizes and specialities.

- Integration with ICU setups (learn more here).

- After-sales support for validation and maintenance.

Final Thoughts

A Modular Operation Theatre is more than an architectural solution—it’s a life-saving environment. Every surface, every air vent, and every component is designed with one purpose: to protect patients and medical teams from infection while enabling advanced surgical care.

For hospitals, diagnostics labs, and healthcare developers, investing in modular OT solutions is not just about meeting compliance—it’s about building trust, improving outcomes, and preparing for the future of healthcare.

AUM Industries brings decades of expertise in modular OT setups, ICU infrastructure, cleanroom construction, and advanced door systems. By combining engineering excellence with deep industry knowledge, we deliver turnkey solutions that are ready to use, reliable, and regulatory compliant.

👉 Want to get started? Contact us today for a free consultation.